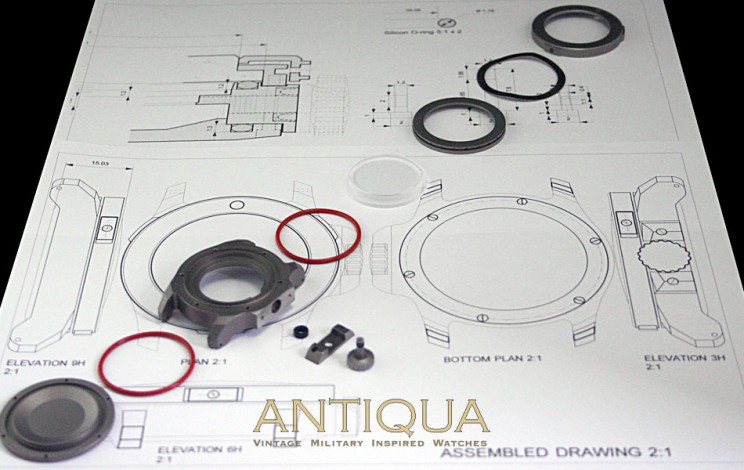

Like all Antiqua watches, each part is carefully researched, designed and drawn in-house. There are no available molds, catalogue cases or standard parts to speak of. The Kilometre is no different as the major draw of the watch is its design and construction.

Image showing the construction drawing, and parts lists.

The case is broken down into:

- Bezel

- Bezel Spring

- Bezel/ Glass retaining ring

- Stepped Sapphire

- Top O-ring

- Main Case

- Bottom O-ring

- Caseback

- Energised Lip Seal

- Crown Protector

- Crown

The Bezel/ Glass retaining ring is held in place by 6 screws from the underside of the maincase, and the caseback is then held to the Main Case by a further 6 screws. The Bezel is then fitted to the top of the retainer by 3 crews from the side which also act as 2.5minute indents. Overall there are 17 screws that hold the entire case together.

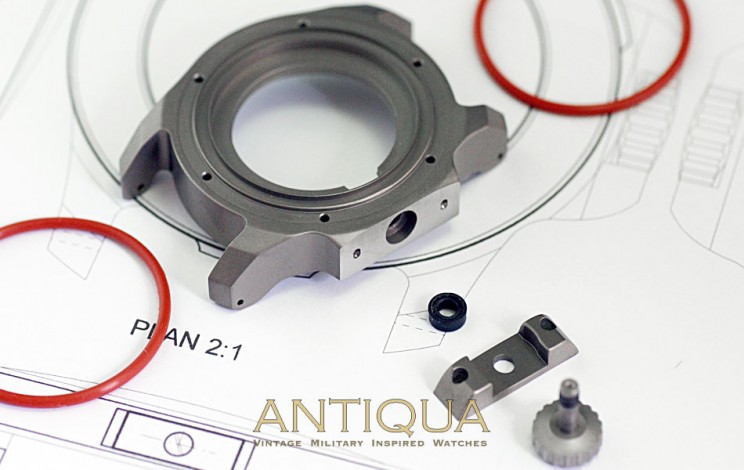

Image showing Bezel, Bezel Spring and Bezel/ Glass Retaining Ring

The image above shows the detents for the 3 screws to sit on the side of the retaining ring. It also shows the track and groove system to hold the bezel in place. The bezel is activated by pushing it down, instead of just turning so that no accidental turning of the bezel is possible.

Image showing the Crown/ Crown Protector/ Energised Lip Seal assembly

An energised lip seal is used instead of a screw down crown system. The lip seal tightens around the crown as water pressure increases. It is a highly novel idea which allows for a stronger crown, and fail safe waterproofing of the crown. The crown itself also utilises 3 o-rings which is necessary for the 1000m water resistance.

Image showing the Swiss made AM200 movement and red Viton O-rings

A modified and customised swiss made movement powers the watch and is fully fitted to the main case without the use of a movement ring. This reduces the weight of the watch, and is only made possible by very strict tolerances. The image above shows how the case is constructed from the bottom, with the screws for the retaining ring in place and the additional 6 holes for the caseback screws. Notice the size of the O-rings used for the watch again to maintain it’s water resistance.